Basic Info.

Model NO.

Y41-63

C Frame Hydraulic Press Safety Technical

GB3915-1885

Structure

Welded C Frame Adopts High Qualified Steel

Structure Process

Aging Treatment to Eliminate Welding Stress

Piston Rod Surface

Intermediate Frequency Quenching Treatment

Hardness

Above HRC45 Then for Chrome Plated Process

Hydraulic Control System

Advanced Integrated Structure

Electrical Control System

PLC Programmable Control Technology

The Emergency Stop Button

on The Operation Panel

Type

C Frame Hydraulic Press

Certification

ISO9001, CE

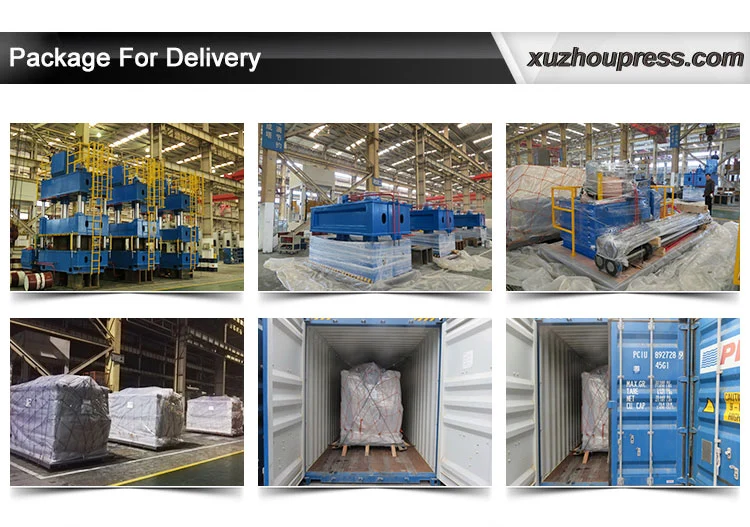

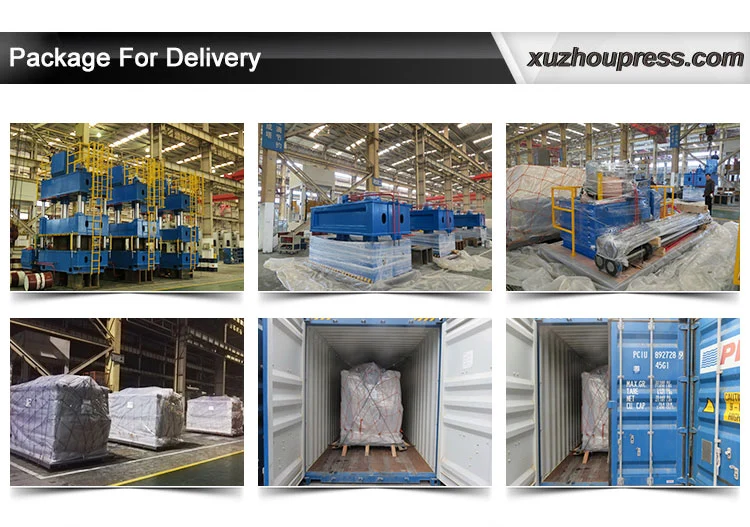

Transport Package

Iron Steel Pallete

Specification

Y41-63

Trademark

XZprestek

Origin

Jiangsu

HS Code

846291000

Production Capacity

3000 Sets /Year

Product Description

SERVO 63TON C FRAME HYDRAULIC PRESS

-table size: min. 600x800mm

-speed: Upward 10-100 mm/s

Downward 10-100 mm/s

If confirmed, we will send you design for confirmation .

1. Technical Parameters :

2. Technical Description :

2.1 Key Components

2.2 Accessories :

2.3. Structure:

C Frame is made of high qualified steel plate welding fuselage, processing aging treatment after welding, to eliminate the welding stress, to ensure that the service life of machine and precision of the persistence.

The press machine consists of fuselage, the main oil cylinder, slider, Stroke limited Device and etc .

2.4 Hydraulic System :

Hydraulic system introduced two- way cartridge valve structure, the design reasonable and structure compactly, reduces the pipeline connection and the leakage points. Motor oil pump on side of machine . Power pump station adopts servo control system with high operating accuracy, fast response , energy saving and consumption reduction.

The hydraulic system is reliable and free of leakage. The oil pump adopts axial plunger pump, the cylinder sealing ring adopts high-quality sealing ring. The pressure gauge is the anti-seismic pressure gauge, the pressure hold time can be adjustable .

C Frame Sliding block rise and fall steady, guide reliable, with four guide pillar guide.

2.5 Electrical Power System

The electric system adopt imported PLC. Main electric components chosen Schneider products. voltage 380 v, 50 hz frequency.

Press stroke control using non-contact proximity switch.

Set with adjustment and semi-automatic function switches on operation panel, emergency stop buttons, and double hands run buttons control.

3. Standard of Technical and Precision :

JB/T3818-1999 <Technical conditions of hydraulic press>

GB3915-1885 <Safety condition of hydraulic press >

JB/T9958.2-1999 C Frame Hydraulic Press Precision>

4. Technical documents:

a. A set of manual (including foundation drawing, Hydraulic principle diagram, electrical diagram, general layout, structural chart, maintenance manuals, and etc)

b. Certificate

c. Packing list

5. Delivery :

-table size: min. 600x800mm

-speed: Upward 10-100 mm/s

Downward 10-100 mm/s

If confirmed, we will send you design for confirmation .

1. Technical Parameters :

| Item | Unit | Y41-63 | |

| Nominal Pressure | kN | 630 | |

| Max.pressure of liquid | Mpa | 25 | |

| Stroke Length | mm | 500 | |

| Throat depth | mm | 320 | |

| Opening Height | mm | 800 | |

| Speed of Slide | Downward Stream | mm/S | 10-100 (adjustable ) |

| Working | mm/S | 10-20 (adjustable ) | |

| Upward Stream | mm/S | 10-100 (adjustable ) | |

| Lower -Table Size | L.R. | mm | 800 |

| F.B. | mm | 600 | |

| Upper- Table Size | L.R. | mm | 550 |

| F.B. | mm | 450 | |

| Operation Height | mm | 700 | |

| Power of Motor | KW | 7.5 | |

2. Technical Description :

2.1 Key Components

| No | Components | Manufacture Brands | Notes |

| 1 | Servo Pump | SUNNY | Axial Piston Pump |

| 2 | Servo Motor | Inovance,ESTUN | |

| 3 | PLC | Janpan Mitsubishi | FX series |

| 4 | Touch Screen | Taiwan Esayview | |

| 5 | Cylinder Oil Sealings | ARET Imported Material | Sliding seal |

| 6 | Cartridge Valves | Jining Taifeng | |

| 7 | Prefill Valves | Huadong | |

| 8 | Electrical Components | France Schneider |

2.2 Accessories :

| No | Model | Quantity | Notes |

| 1 | Anchor Foundation Bolts | 1 Set | Press body and Power System |

| 2 | Wearing Sealings | 1 set | Pipes and Power System |

2.3. Structure:

C Frame is made of high qualified steel plate welding fuselage, processing aging treatment after welding, to eliminate the welding stress, to ensure that the service life of machine and precision of the persistence.

The press machine consists of fuselage, the main oil cylinder, slider, Stroke limited Device and etc .

2.4 Hydraulic System :

Hydraulic system introduced two- way cartridge valve structure, the design reasonable and structure compactly, reduces the pipeline connection and the leakage points. Motor oil pump on side of machine . Power pump station adopts servo control system with high operating accuracy, fast response , energy saving and consumption reduction.

The hydraulic system is reliable and free of leakage. The oil pump adopts axial plunger pump, the cylinder sealing ring adopts high-quality sealing ring. The pressure gauge is the anti-seismic pressure gauge, the pressure hold time can be adjustable .

C Frame Sliding block rise and fall steady, guide reliable, with four guide pillar guide.

2.5 Electrical Power System

The electric system adopt imported PLC. Main electric components chosen Schneider products. voltage 380 v, 50 hz frequency.

Press stroke control using non-contact proximity switch.

Set with adjustment and semi-automatic function switches on operation panel, emergency stop buttons, and double hands run buttons control.

3. Standard of Technical and Precision :

JB/T3818-1999 <Technical conditions of hydraulic press>

GB3915-1885 <Safety condition of hydraulic press >

JB/T9958.2-1999 C Frame Hydraulic Press Precision>

4. Technical documents:

a. A set of manual (including foundation drawing, Hydraulic principle diagram, electrical diagram, general layout, structural chart, maintenance manuals, and etc)

b. Certificate

c. Packing list

5. Delivery :